Common Process of Metal Stamping

The Basics of Metal Stamping

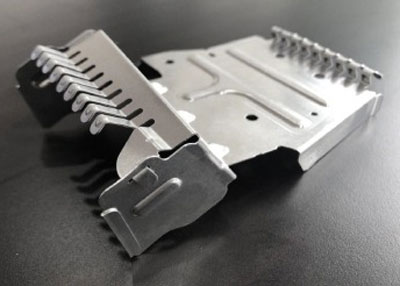

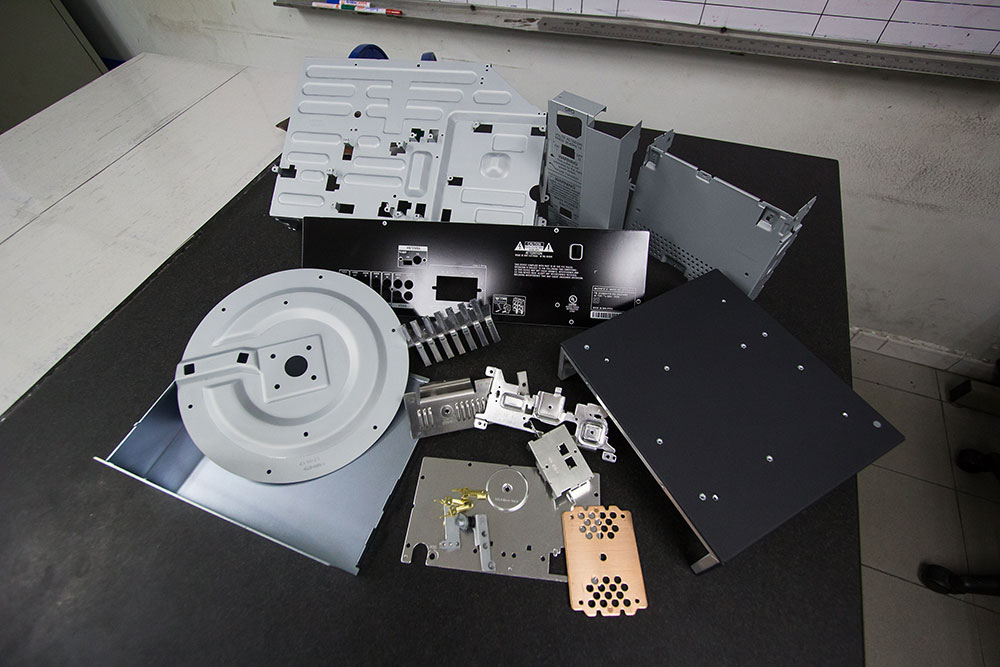

Metal stamping is a complex process that transforms metal sheets into usable parts or components. Besides, the metal stamping process happens when the metal is fed into a press where the stamping tool (commonly known as a die) helps to turn the metal into the required shape.

It is a complex process that includes numerous metal forming techniques or processes and we will be explaining the common processes of metal stamping a little further inside the article.

Common Process of Metal Stamping

- Forming

Forming is the process of applying force to convert the flat metal into another shape. In this process, the metal can be transformed into a complex shape from a simple shape. - Blanking

This is the most basic technique in the metal stamping process, it is the process when the metal sheet is fed into the press and the die cuts out into the required shape. In this process, the resulting piece of metal sheet is commonly called a blank. - Drawing

This process is more complicated because this process is how the vessels or deep depressions in the metal sheets are formed. To modify the shape of a substance, tension is utilized to precisely drag it into a cavity. In this process, the material might be stretched while it’s drawn; however, the technician will try to avoid and keep the material intact as much as possible. For instance, the metals that are made by drawing are sinks and cooking equipment. - Bending

Bending is a process that is performed after the drawing process and this is the process of placing a metal sheet on a specially designed die and pushing it with a ram to transform it into a required bend.